Is it better to place the steering servo on the steering axle or on the chassis beam for a crawler? If placed on the chassis beam, would the distance between the axle and the beam change cause the front wheels to steer unintentionally? But why is this design common in many RC cars on the market now?

Here’s an answer from an experienced player in the industry:

If the steering servo is well-designed on the chassis beam of a YIKONG crawler, the steering linkage and the axle’s thrust rod should be parallel. During compression, there should be minimal steering fluctuation. For the thrust rod on the axle, its up-and-down motion actually follows an arc around the thrust rod, with the fixed point on the chassis beam as the center. During compression, the axle not only moves up and down but may have slight lateral displacement.

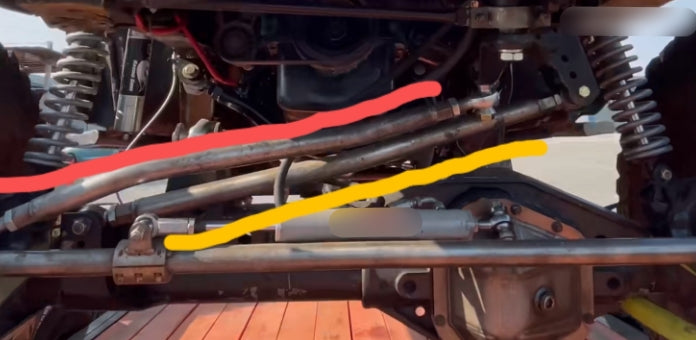

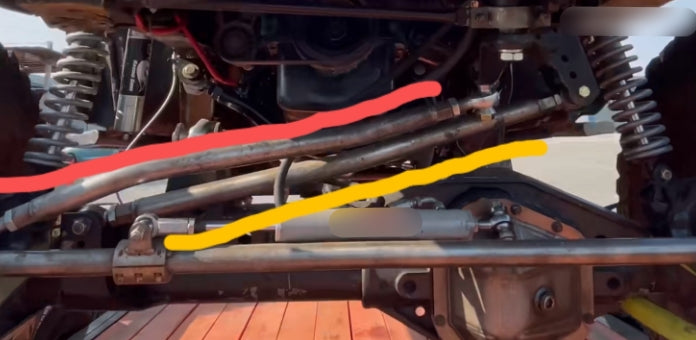

As shown in the image: red is the steering linkage, and yellow is the thrust rod.

If the length and parallelism match, the movement paths of the axle and steering assembly can be aligned. In theory, this design won’t cause fluctuating steering.

In practice, there may still be a slight issue with this structure on a crawler, but if the design considered this factor, and it wasn’t done mindlessly, the problem should be minimal and subtle.

The key is that crawlers aren’t high-speed cars and aren’t used for speed racing. This doesn’t significantly affect the control; it’s just a matter of personal perception.